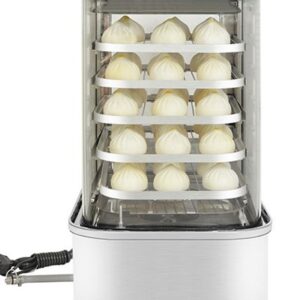

Electronic 6-layer steamer introduction:

The electronic 6-layer steamer is a piece of equipment used in commercial kitchens or food processing plants, specifically designed for steaming buns, steamed buns, dumplings, and other dough-based foods. This type of steamer typically uses an electronic control system and features multiple steaming trays, allowing for the simultaneous steaming of large quantities of food, thereby improving work efficiency and production capacity. Here are some characteristics and functions of the electronic 6-layer steamer:

1)Multi-layer design: The electronic 7-layer steamer usually comes equipped with multiple steaming trays, which can be used to steam different types of food at the same time, or to steam the same type of food on different levels to meet various needs.

2)Electronic control: This steamer uses an electronic control system, which allows for precise control of steaming time, temperature, and other parameters to ensure that food is steamed evenly and consistently.

3)Energy-efficient: The electronic steamer typically uses an energy-efficient heating method, such as steam heating or electric heating, which can quickly generate steam and save energy.

4)Safe and reliable: The equipment usually comes equipped with safety protection devices, such as overheat protection and low-water protection, to ensure the safety of both the operator and the equipment.

5)Easy to clean: The design of the steamer usually takes into account the convenience of cleaning, with steaming trays and the interior made from materials and designs that are easy to clean, facilitating daily maintenance and hygiene management.

6)Adjustable temperature and time: Users can adjust the steamer’s temperature and steaming time according to different food types and steaming requirements to achieve the best steaming results.

7)Easy to move: Some electronic 6-layer steamers may be equipped with wheels, making them easy to move around the kitchen or workspace.

8)Large capacity: With multiple steaming trays, the electronic 6-layer steamer can steam large quantities of food at once, making it suitable for restaurants, cafeterias, hotels, and other settings that require large-scale steaming.

When selecting an electronic 6-layer steamer, it is necessary to consider factors such as the types of food to be steamed, production volume, kitchen space, and more, to ensure that the chosen equipment meets actual needs. Additionally, the brand, quality, and after-sales service of the equipment are also important factors to consider when making a purchase.

TECHNICAL PARAMETERS

| Specification | |||

| Model NO. | 6layers | Temperature Control | Mechanical Thermostat |

| Temperature Type | Single-temperature | Defrost Type | |

| Function | Cold Storage & Freezing | Power Source | Electricity |

| Showcase for | Refrigerate Display | Performance | Cooking |

| Use for | Commercial | Usage | Cooking Food |

| Temperature Control | Computer Thermostat | Door Type | No Door |

| Application | Commercial | Package | Hard Carton |

| Specification | 480*548*875 mm | Trademark | Changcai |

| Custom Logo | Available | Use Place | Convenient Store, Fast Shop, Super Market |

| Origin | China | Transport Package | Paper Carton, Pallet |

| Style | Standing | Material | Glass+Stainless steel |

| Production Capacity | 10000pcs/year | HS Code | 8419810000 |

ADVANTAGE

The 6-layer electronic steamer has several advantages in the food processing and catering industry. Here are some of the main benefits:

1)Efficient Production: The multi-level design allows for the simultaneous steaming of large quantities of food, increasing production efficiency and making it suitable for high-demand environments such as restaurants, cafeterias, hotels, and food processing plants.

2)Precise Control: The electronic control system enables accurate adjustment of temperature and time, ensuring consistency and quality in the food steaming process, and reducing human error.

3)Energy-saving and Eco-friendly: Compared to traditional steamers, electronic steamers typically use more efficient heating methods, reducing energy waste and lowering operating costs.

4)Safe and Reliable: Equipped with safety protection devices such as overheat protection and low-water protection, ensuring the safety of the equipment and the operator.

5)Easy to Clean and Maintain: Designed with consideration for hygiene and maintenance convenience, helping to maintain kitchen hygiene standards and reducing the time spent on cleaning and maintenance.

6)Flexibility: The multi-level structure can be adjusted according to needs, accommodating different sizes and types of food for steaming.

7)Space-saving: The vertical multi-level design saves kitchen space compared to horizontally extended equipment.

8)Easy to Move: Some models are equipped with wheels, making it convenient to move around the kitchen and improving work flexibility.

9)Customizability: Electronic steamers can be provided with different configurations and features to meet specific steaming requirements, tailored to the needs of different customers.

10)Extends Food Freshness: The high temperature during the steaming process can kill bacteria and microorganisms, helping to extend the shelf life of food.

When selecting a 6-layer electronic steamer, it is important to consider the quality, brand, after-sales service, and whether it meets specific food safety standards and certifications, to ensure a return on investment and long-term satisfaction with the equipment.